聯系人:張總

電話:0510-85580289

傳真:0510-85580289

手機:13771507750

郵箱:wxzkjc@126.com

地址1:無錫市濱湖區胡埭鎮丁香東路18號

地址2:無錫市濱湖區胡埭鎮文冠路20號

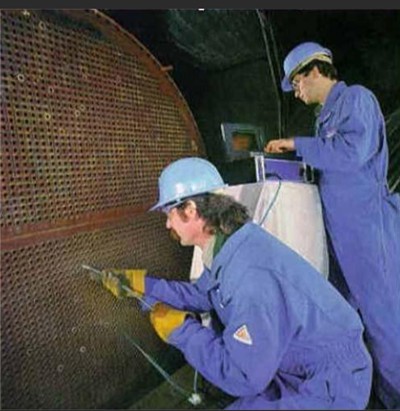

官網:www.qscfood.com.cn電磁檢測是無損檢測中的一種,用于查找物體中的缺陷。每種測試都有不同的應用和方法。所有測試都使用電場或磁場,有些測試同時使用電場或磁場。根據所使用的測試類型,電流或磁場的變化,當它通過或圍繞被測試的物體發生電磁轉化時,則信號指向可能存在的缺陷或缺陷。

渦流檢測技術是利用電磁感應原理,通過測定被檢工件內感生渦流的變化來無損評定導電材料及其工件的某些性能,或發現缺陷的無損檢測。

與渦流伴生的感應磁場與原磁場疊加,使得檢測線圈的復阻抗發生變化。導體內感生渦流的幅值、相位、流動形式及其伴生磁場受導體的物理特性影響,因此通過監測檢測線圈的阻抗變化即可非破壞地評價導體的物理和工藝性能,此即渦流檢測的基本原理。

常規渦流檢測是一種表面或近表面的無損檢測方法。由于渦流因電磁感應而生,因此進行渦流檢測時,檢測線圈不必與被檢材料或工件緊密接觸,不需用耦合劑,檢測過程不影響被檢材料或工件的性能。

與其它無損檢測方法比較,渦流檢測的主要特點有:

對導電材料表面和近表面缺陷的檢測靈敏度較高;應用范圍廣,對影響感生渦流特性的各種物理和工藝因素均能實施監測;不需用耦合劑,易于實現管、棒、線材的高速、高效、自動化檢測;在一定條件下,能反映有關裂紋深度的信息;可在高溫、薄壁管、細線、零件內孔表面等其它檢測方法不適用的場合實施監測。渦流檢測的缺點是檢測效率相對較低;另外,僅依靠渦流檢測通常也難以區分缺陷的種類和形狀。

An electromagnetic test is a class of non-destructive testing used to find defects in an object. Each type of test has a different application and methodology. All tests use electricity or magnetic fields, with some using both. Depending on the specific type of testing used, the amount of electrical current that is reflected, refracted or otherwise conducted through the piece is measured. Changes in the current or magnetic field, as it moves through or around an object being tested, point to possible flaws or defects.

In the past, the term “electromagnetic test” typically referred to eddy-current testing. Eddy-current testing finds defects close to the surface of metal objects. Improvements in testing capabilities, however, have resulted in an ever-expanding number of electromagnetic test options. Other tests such as remote field testing, magnetic flux leakage testing, wire-rope testing and magnetic particle inspection allow users to test for defects in a variety materials, shapes and locations. Using electricity and magnetic fields, each type of electromagnetic test produces a response that points to cracks, heat damage, corrosion or other flaws in a broad range of materials and environments.

Aside from detecting defects, the use of electricity in magnetic fields can also help determine the other unseen properties of metal, earth and soft tissue. Results indicate material thickness, electrical conductivity, the presence of foreign objects and other information. The purpose of any electromagnetic test is to provide the ability to gather information before embarking on expensive or unnecessary digging, dissembling or surgery or to ensure the safety of a manufactured component.

Examples of the many uses of various types of electromagnetic testing can be found in commercial construction and the medical field. For example, pulsed eddy-current testing is used on pipes to determine metal loss without the need to expose the actual pipe. This type of electromagnetic testing can be done from a considerable distance when direct access to the pipe in question is not practical.

上一頁:沒有了…

下一頁:沒有了…

聯系人:張總

電話:0510-85580289

傳真:0510-85580289

手機:13771507750

郵箱:wxzkjc@126.com

地址1:無錫市濱湖區胡埭鎮丁香東路18號

地址2:無錫市濱湖區胡埭鎮文冠路20號

官網:www.qscfood.com.cn